OEM powder metallurgy (PM) parts play a critical role in the development of industrial robots, as they offer high precision, excellent mechanical properties, and cost-efficiency. Powder metallurgy is a manufacturing process where metal powders are compacted and then sintered to form solid, highly durable components. The ability to produce complex shapes and parts with precise tolerances makes PM a preferred method for producing parts used in robotic applications.

Key Powder Metallurgy Parts for Industrial Robots:

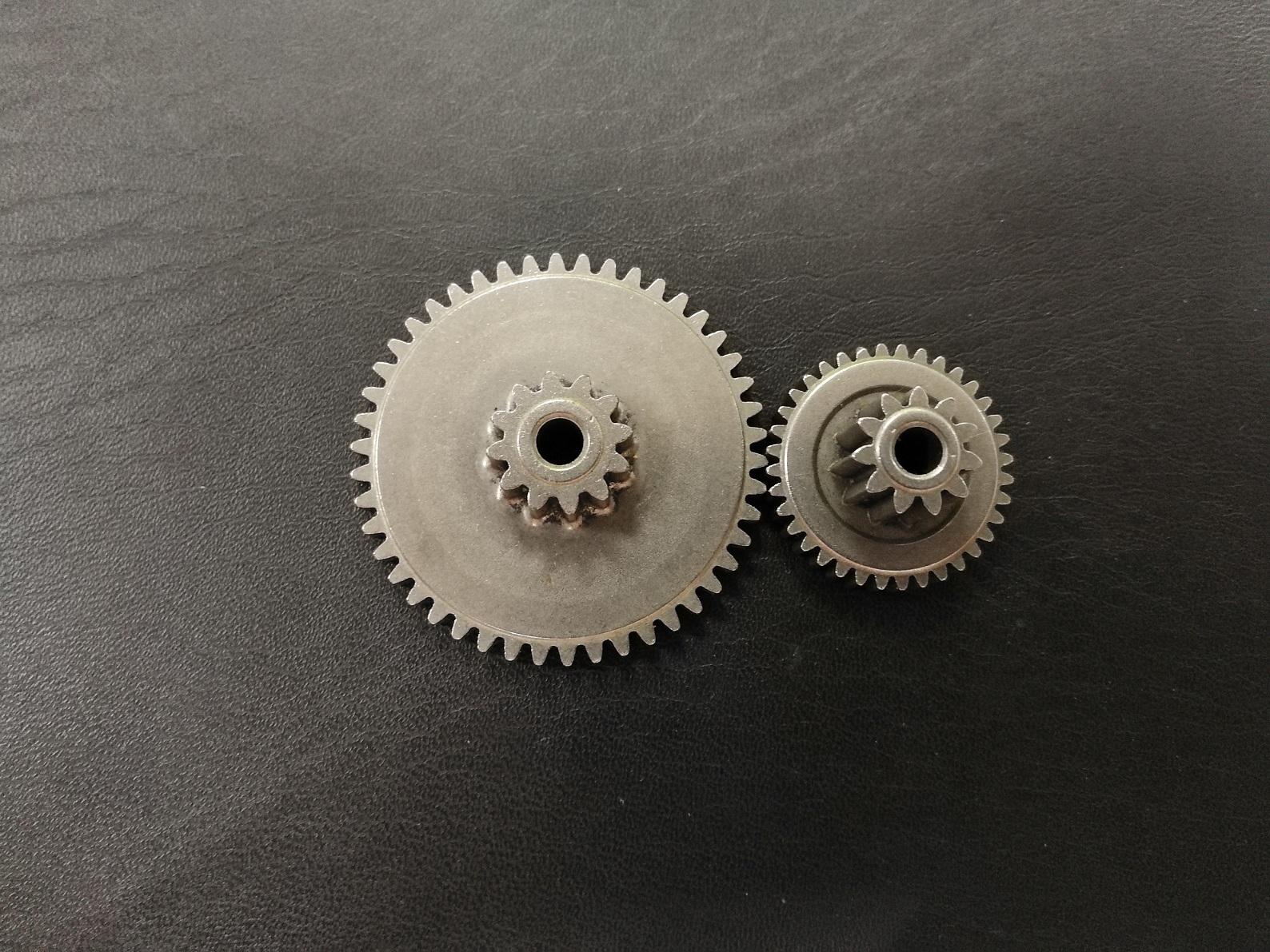

Gears:

Purpose: Gears are essential for transmitting motion and torque in robotic arms and joints.

Advantages: PM allows the production of gears with precise tolerances, smooth finishes, and excellent wear resistance, ensuring long-lasting performance. The ability to create complex gear geometries also optimizes space and function in compact robotic designs.

Bushings and Bearings:

Purpose: Bushings and bearings reduce friction between moving parts in robotic joints, ensuring smooth operation.

Advantages: PM-produced self-lubricating bearings made from materials like bronze or iron can operate without additional lubrication, which is beneficial in high-frequency motion environments like industrial robots.

Structural Components (Housings, Frames, Brackets):

Purpose: These parts form the skeleton of robotic arms and other moving parts.

Advantages: PM enables the production of lightweight yet strong components, which are crucial for maintaining high speed and precision while reducing the overall weight of the robot. The process also allows for intricate and complex part designs.