Powder metallurgy (PM) is widely used in the automotive industry to manufacture parts with complex shapes and high strength. Below are some common PM parts used specifically in the automobile body and doors:

1. Body Parts:

- Structural Brackets:Used for mounting various components to the car body.

- Engine Mounting Brackets:Support the engine and reduce vibrations.

- Chassis Components:Reinforce the frame and provide structural stability.

- Hinges and Supports:Facilitate the movement of doors and hoods.

2. Door Parts:

- Door Lock Components:Pins, latch mechanisms, and lock bodies.

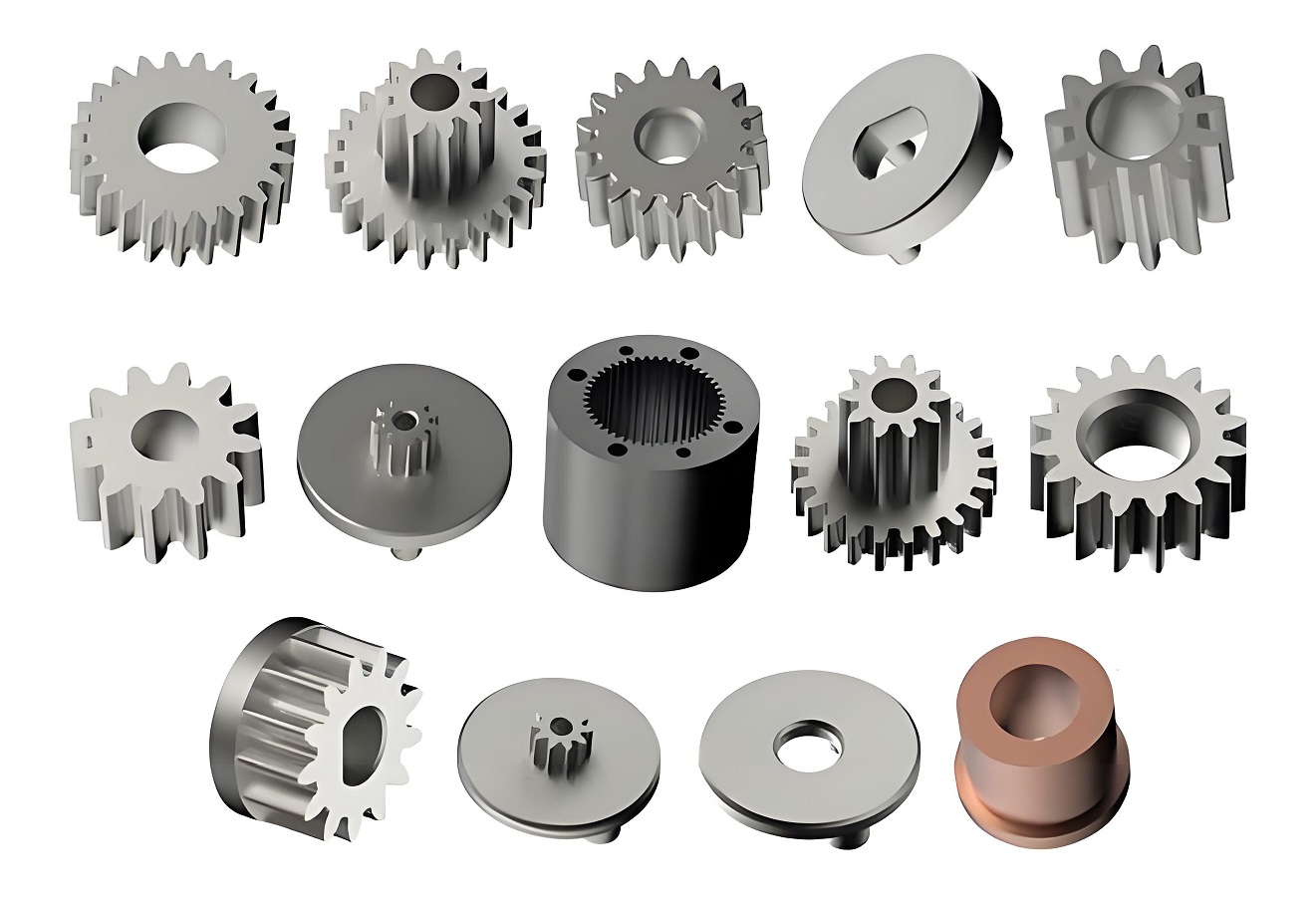

- Window Regulator Gears:Used in power windows to raise and lower the glass.

- Door Handle Components:Gears and other small parts that enable smooth operation.

- Door Hinge Pins:Provide pivot points for door opening and closing.

Advantages of Powder Metallurgy Parts:

1. High Dimensional Accuracy: Reduced need for post-machining, saving time and cost.

2. Complex Shapes: Easily produce intricate geometries that would be challenging with traditional machining.

3. Material Efficiency: Minimal wastage since near-net shape manufacturing is achieved.

4. Superior Mechanical Properties: High strength, hardness, and wear resistance.

5. Lightweight: Can use lightweight alloys to reduce the vehicle’s overall weight.

6. Cost-Effective Production: Ideal for mass production with consistent quality.

7. Reduced Material Loss: Low scrap rate compared to machining from solid materials.

8. Enhanced Surface Finish: Smooth surfaces suitable for aesthetic and functional applications.

9. Corrosion Resistance: Improved by selecting appropriate alloys and post-processing techniques.